Dimensional Digital Twin

Laser Scanning is frequently the first step in Digitizing Physical Objects for incorporating assets their function and performance into a collective digitalization of a facility. This process is commonly known as Digital Transformation.

When the digital transformation is complete and can replicate the real-world environment, it has essentially become a Digital Twin and is the foundation for the Living Model.

The Living Model is a Digital Twin that drives a business model and is the next step for A.I. interaction and generating optimal business solutions.

The Living Model receives operational, environmental and logistical data and constantly updates itself. In addition, it can access identical data parameters from other operating units globally, increasing the knowledge base in real time.

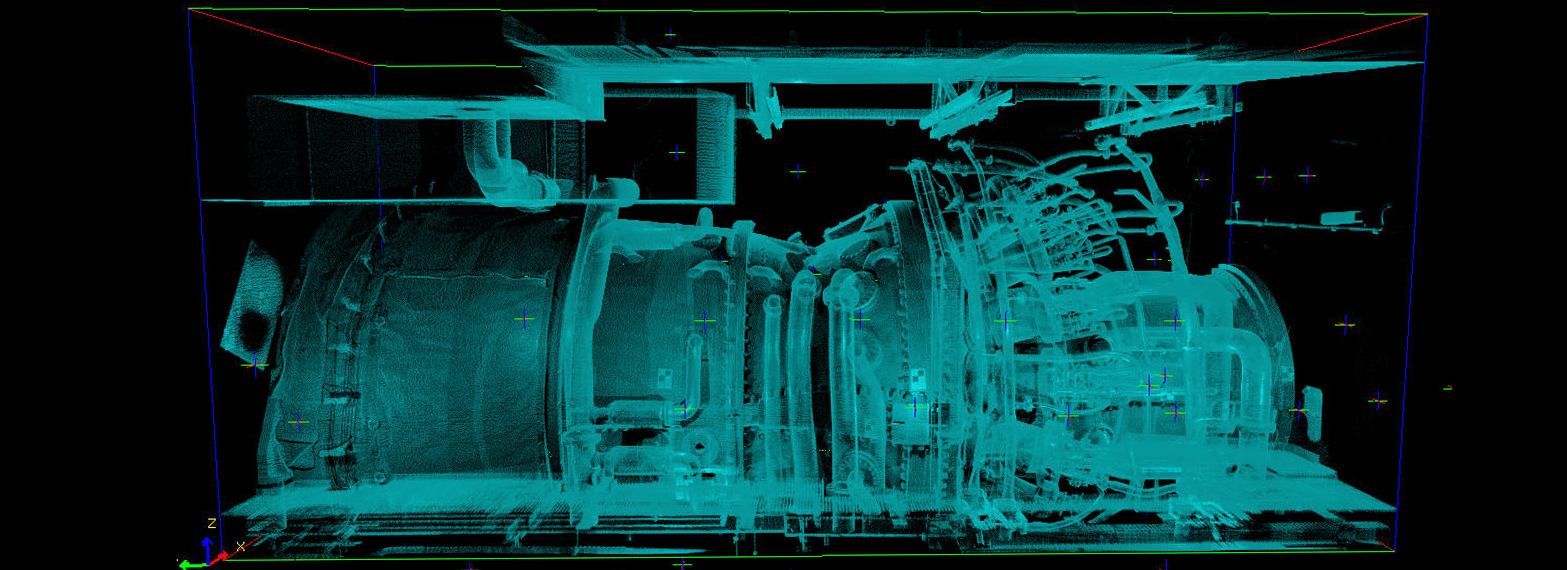

The Dimensional Digital Twin built from scan data is accurate to +/-1/8 ” (+/-3mm) and is a true and accurate real-world digital copy.

A digital twin uses virtual and augmented reality as well as 3D graphic and data modelling to build a virtual model of a process, system, service, product or other physical objects. This digital twin is an exact replica of the physical world. Its exact replica status is maintained through real-time updates.

It is a technology that is applicable to a wide range of environments, including the monitoring of products while they are in use and throughout their life cycle. An example is a Bulk-Power System turbine.

You can use the digital twin within the following asset levels:

Component level – focused on a single, highly critical component within the manufacturing process.

Security Level – Identify Bulk-Power System locations compromised with regards to safety and security.

Asset Level – Creating a digital twin of a single piece of equipment within a production line

System Level – Using a digital twin to monitor and improve an entire production line

Process Level – This looks at the entire manufacturing process from product and process design and development, to manufacturing and production, to distribution and use of the finished product by customers/patients throughout the entire life cycle and for the development of future products.

A digital twin comprises three main elements:

(1) Past data – historical performance data of individual machines, overall processes, and specific systems.

(2) Present data – real-time data from equipment sensors, outputs from manufacturing platforms and systems, outputs from systems throughout the distribution chain, and outputs from systems in other business units including customer service and purchasing.

(3) Future data – machine learning as well as inputs from engineers.